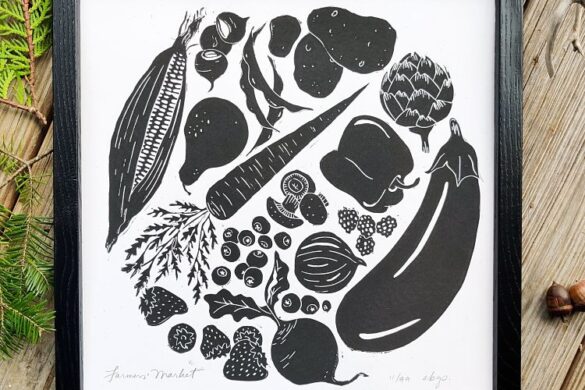

Matt Holmes is a designer maker, whose work explores the point where digital technologies and heritage crafts collide. His practice currently revolves around printing presses, and the craft behind the history of letterpress. Matt employs 3D printing and CNC to build his own printing presses, printed typefaces and printing plates, from which he creates his own inked prints. His goal is to use these new technologies to help preserve and evolve heritage crafts, creating accessible equipment that shares the joy of letterpress.

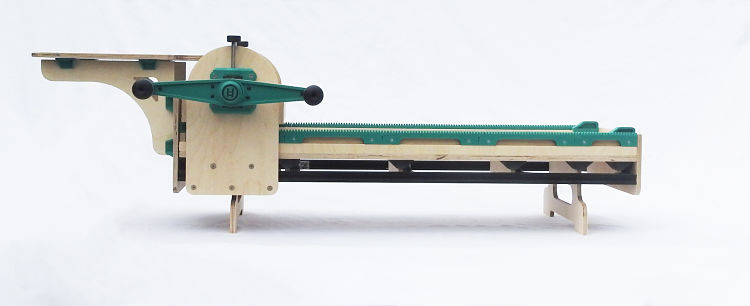

Due to graduate this summer from the University of Plymouth, for his final major project Matt wanted to analyse the accessibility of equipment for heritage crafts, and in particular, letterpress. “I realised once I left the university, I would no longer be able to play in the letterpress workshops and keep using and learning this skill and art form. Equally, I could never afford the cost of an original press, nor could I really afford the space it would need either” explains the craftsman. Thus, Matt utilised his experience using 3D printers to develop a way of using digital fabrication to build a new variation of a letterpress printing press. In particular, one that operated as close to the proofing presses he had fallen in love with using at University; “to help to keep the tactile skills and joy of their operation as part of the experience, but blend traditional techniques with the modern digital world in a tactile, physical way“.

Due to graduate this summer from the University of Plymouth, for his final major project Matt wanted to analyse the accessibility of equipment for heritage crafts, and in particular, letterpress. “I realised once I left the university, I would no longer be able to play in the letterpress workshops and keep using and learning this skill and art form. Equally, I could never afford the cost of an original press, nor could I really afford the space it would need either” explains the craftsman. Thus, Matt utilised his experience using 3D printers to develop a way of using digital fabrication to build a new variation of a letterpress printing press. In particular, one that operated as close to the proofing presses he had fallen in love with using at University; “to help to keep the tactile skills and joy of their operation as part of the experience, but blend traditional techniques with the modern digital world in a tactile, physical way“.

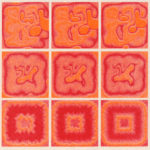

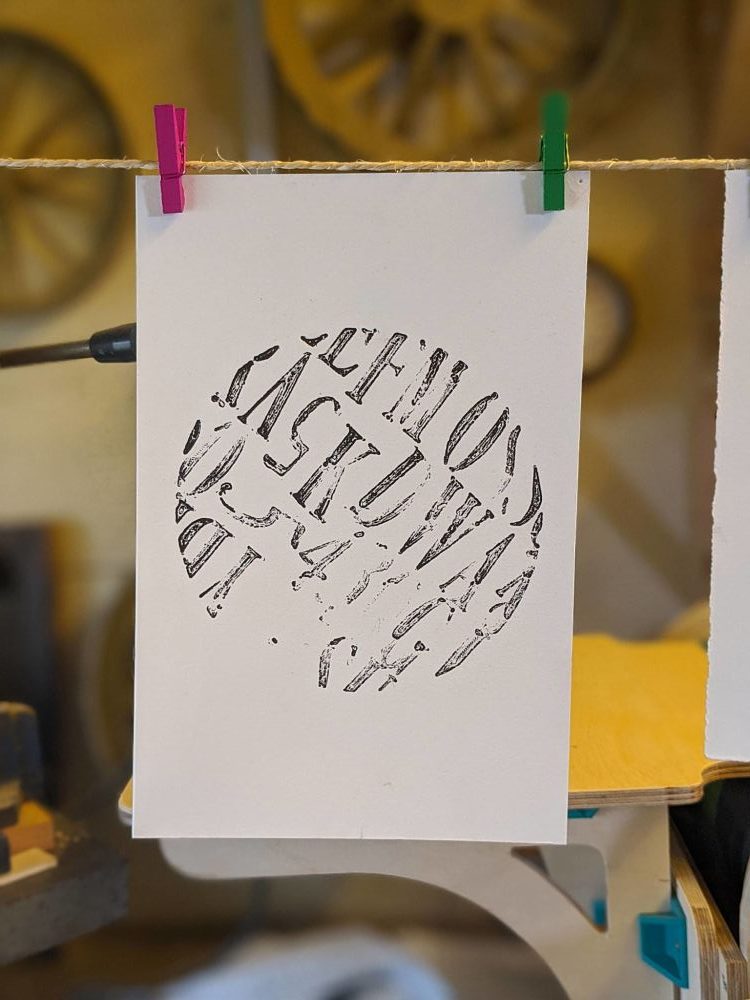

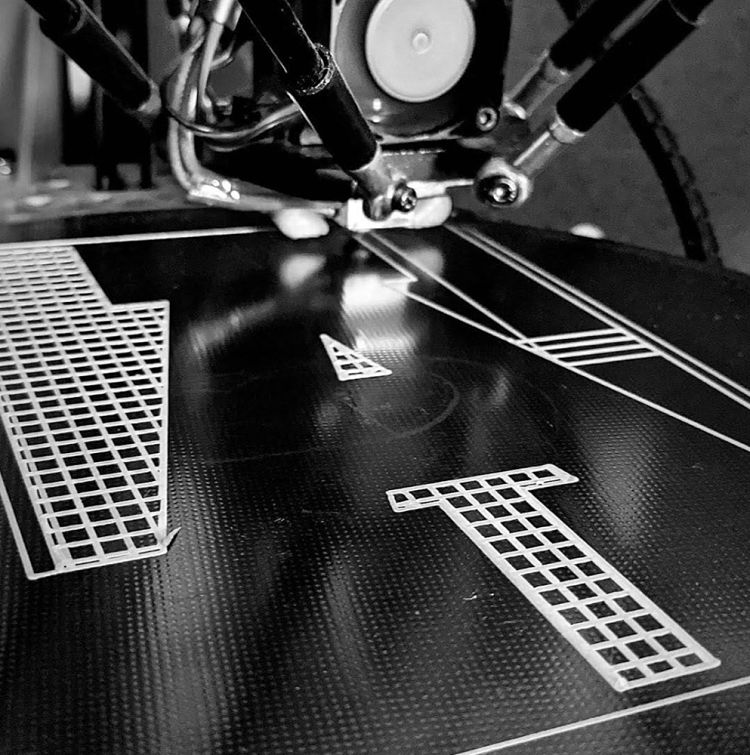

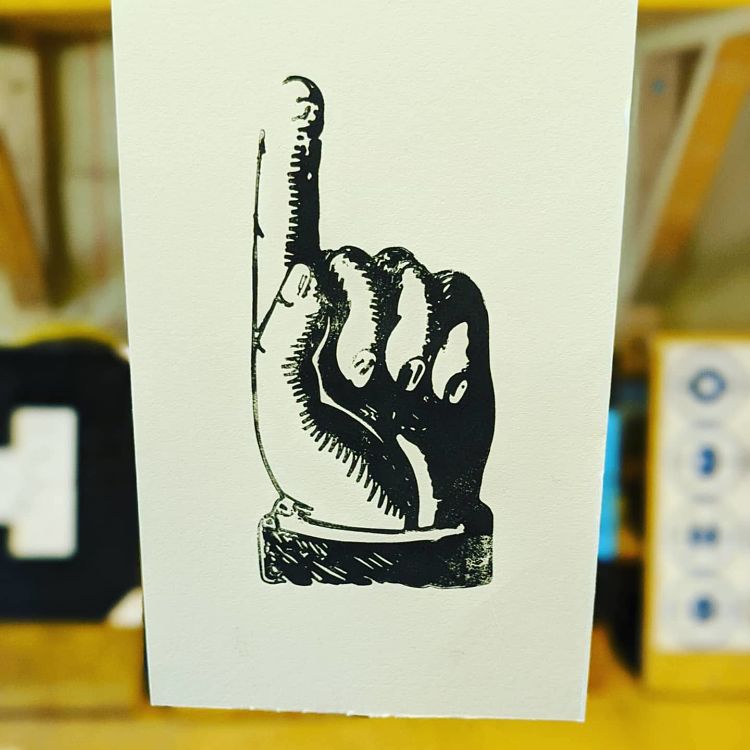

The Press Print project is the direct result of this exploration; a prototype 3D printed and plywood printing press. Matt’s print work also stems from this, as he uses the same tools that created the press to create his own printing plates and type pieces. “I enjoy exploring the interesting collision between the digitally created and manufactured type, and the wonderfully analogue process of creating the print” states the maker.

The Press Print project is the direct result of this exploration; a prototype 3D printed and plywood printing press. Matt’s print work also stems from this, as he uses the same tools that created the press to create his own printing plates and type pieces. “I enjoy exploring the interesting collision between the digitally created and manufactured type, and the wonderfully analogue process of creating the print” states the maker.

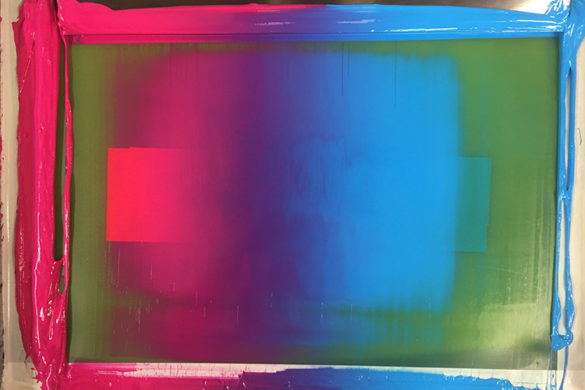

Matt thrives in learning through experimentation and play, and enjoys analysing the way the 3D printer creates type pieces, and the traces and marks its manufacture leaves in the inked print. He desribes; “It is sometimes messy (3D printers can and do go wrong, sometimes spectacularly) and sometimes frustrating (when inked prints don’t work out well in practice) but it is also incredibly exciting and fulfilling to work through the problems and find new and unexpected results along the way“.

Matt thrives in learning through experimentation and play, and enjoys analysing the way the 3D printer creates type pieces, and the traces and marks its manufacture leaves in the inked print. He desribes; “It is sometimes messy (3D printers can and do go wrong, sometimes spectacularly) and sometimes frustrating (when inked prints don’t work out well in practice) but it is also incredibly exciting and fulfilling to work through the problems and find new and unexpected results along the way“.

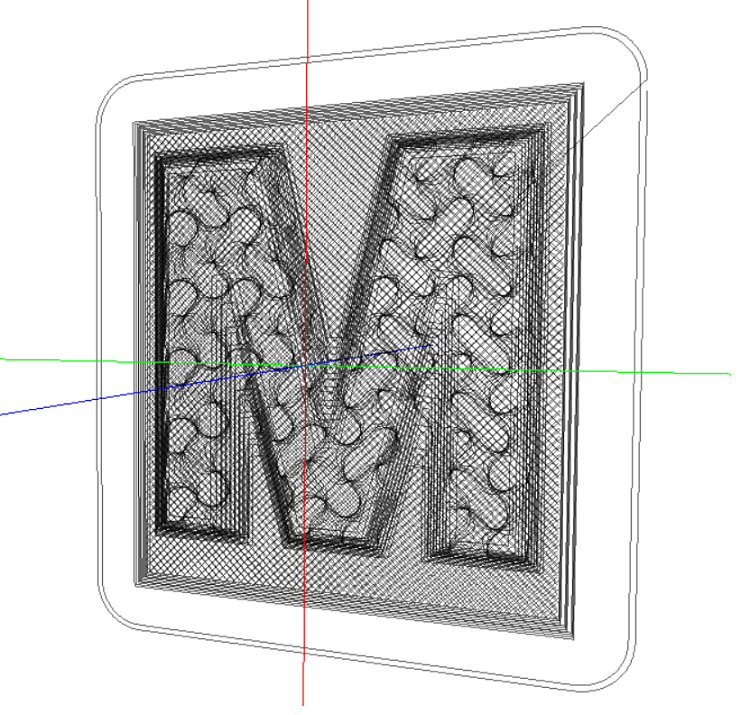

The software Matt uses crosses the graphic/3D boundaries. In the 2D realm, Illustrator is his chosen programme for manipulating shapes and type. However, the majority of his work happens in the 3D realm, where he uses CAD programs such as Fusion360, Meshmixer, and Rhino to design the components of his printing presses, create the type pieces, and work with 3D scans before 3D printing and CNC machining. An Anycubic Kossel 3D printer is the workhorse of Matt’s manufacturing, serving as a rapid prototyping facility, and also as a type foundry.

The software Matt uses crosses the graphic/3D boundaries. In the 2D realm, Illustrator is his chosen programme for manipulating shapes and type. However, the majority of his work happens in the 3D realm, where he uses CAD programs such as Fusion360, Meshmixer, and Rhino to design the components of his printing presses, create the type pieces, and work with 3D scans before 3D printing and CNC machining. An Anycubic Kossel 3D printer is the workhorse of Matt’s manufacturing, serving as a rapid prototyping facility, and also as a type foundry.

As a lover of big chunky type and bold colours, Matt is inspired by the work of designers such as Aaron Draplin and Anthony Burrill. The equipment he uses also heavily influences his creations, both in the development of the printing press, and in the 3D printed type. He enjoys testing the capability of the machines, and investigating the unique aesthetic that the two create together. Matt also has the letterpress technician at the University of Plymouth to thank for teaching him the craft; “despite me not coming from a traditionally print-focused course, he was always happy to chat and always encouraging for me to work with letterpress in new and exciting ways from a maker perspective“.

As a lover of big chunky type and bold colours, Matt is inspired by the work of designers such as Aaron Draplin and Anthony Burrill. The equipment he uses also heavily influences his creations, both in the development of the printing press, and in the 3D printed type. He enjoys testing the capability of the machines, and investigating the unique aesthetic that the two create together. Matt also has the letterpress technician at the University of Plymouth to thank for teaching him the craft; “despite me not coming from a traditionally print-focused course, he was always happy to chat and always encouraging for me to work with letterpress in new and exciting ways from a maker perspective“.

Matt is returning to Plymouth in the autumn for his masters degree, where he plans to invest in and develop the Press Print project, with the goal to create functioning kits and plans for others to follow to create presses and printing equipment of their own. He hopes to also scale up the A4 press, setting his sights on a press capable of A3+, stepping up the number of features and usability, as well as taking the portable presses on the road to exhibitions. For his print work, Matt aims to continue to push the aesthetic that comes with 3D print, highlighting the process and developing his own style. He concludes; “Eventually, I would love to have my own studio where I can create and sell my own prints, but also have the capacity to run workshops and events to those who would like to dabble in this combination of skills and processes“.

Matt is returning to Plymouth in the autumn for his masters degree, where he plans to invest in and develop the Press Print project, with the goal to create functioning kits and plans for others to follow to create presses and printing equipment of their own. He hopes to also scale up the A4 press, setting his sights on a press capable of A3+, stepping up the number of features and usability, as well as taking the portable presses on the road to exhibitions. For his print work, Matt aims to continue to push the aesthetic that comes with 3D print, highlighting the process and developing his own style. He concludes; “Eventually, I would love to have my own studio where I can create and sell my own prints, but also have the capacity to run workshops and events to those who would like to dabble in this combination of skills and processes“.

www.holmesylogic.co.uk

@holmesylogic

Anyone working with print can apply to join our Official POP Membership community here.

You might like...

- Mark Frendo | Danger UXARD - April 18, 2024

- Sue Lewry | The Creative Cycle - April 17, 2024

- Container - April 16, 2024