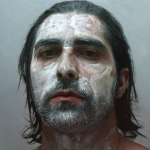

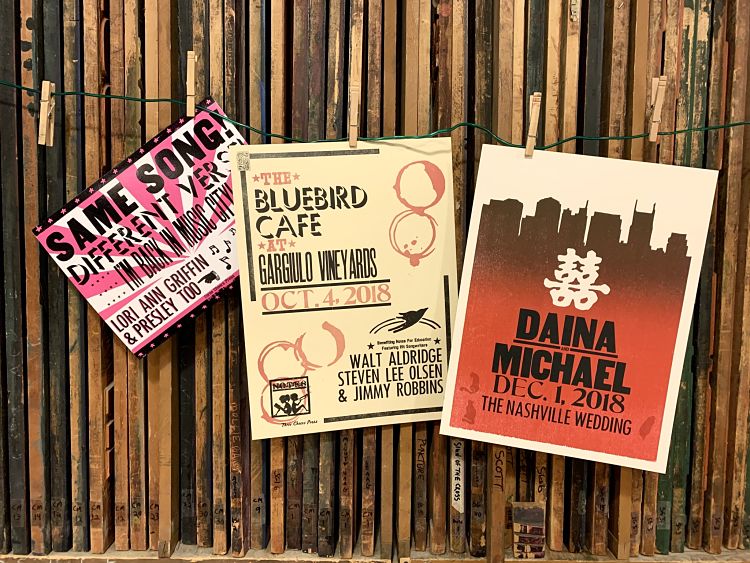

Letterpress printer, digital designer, and letterpress equipment mechanic, Cory Wasnewsky, is the face behind Three Cheers Press. In his off hours after working his day job at Hatch Show Print, Cory creates posters for musicians, events, and businesses, as well as the occasional business card, wedding invite, and birth announcement. He also completes design work for logos and product design, including souvenir baseballs, cornhole boards, t-shirts, and book covers.

Cory received a BFA from Montserrat College of Art in 2014 with a concentration in Book Arts, and started Three Cheers Press during a class in 2013. During his junior year Cory interned at Montserrat’s in-house print shop, and for a summer at Hatch Show Print in 2013. He became a a full-time employee at Hatch in October of 2014 after completing his undergraduate degree, and has gone on to gain a great mechanical knowledge of Vandercook and Miehle cylinder presses, as well as experience maintaining and repairing trim saws, guillotine-style paper cutters, and routers.

Cory received a BFA from Montserrat College of Art in 2014 with a concentration in Book Arts, and started Three Cheers Press during a class in 2013. During his junior year Cory interned at Montserrat’s in-house print shop, and for a summer at Hatch Show Print in 2013. He became a a full-time employee at Hatch in October of 2014 after completing his undergraduate degree, and has gone on to gain a great mechanical knowledge of Vandercook and Miehle cylinder presses, as well as experience maintaining and repairing trim saws, guillotine-style paper cutters, and routers.

Music plays a big part in Cory’s process; “putting some music while working gets my mind in a good place for creating”. Looking at record covers, book covers, and other printers’ work is also almost a daily happening. Rather than a specific person or persons, Cory is very drawn to vintage label designs, sign painting, old show cards, trading cards, and illustration and design from the late 19th century and early 20th century because of their “beautiful colour combinations, flourishes, and composition”.

Music plays a big part in Cory’s process; “putting some music while working gets my mind in a good place for creating”. Looking at record covers, book covers, and other printers’ work is also almost a daily happening. Rather than a specific person or persons, Cory is very drawn to vintage label designs, sign painting, old show cards, trading cards, and illustration and design from the late 19th century and early 20th century because of their “beautiful colour combinations, flourishes, and composition”.

His pieces begin as thumbnail sketches of various compositions that he plays around with until he has a layout he is happy with. Then he moves forward with typesetting the design, making proofs to compile so he has a reference once he moves to press. “I have very strong attention to quality when printing, ensuring that the final product is printed as flawless as possible” says the printmaker. Some of Cory’s favourite printing to do is on the high-speed automatic Miehle presses; “there’s something very satisfying to me about going through the set-up and metal checklist to adjust the press to print the best quality for each and every job”.

His pieces begin as thumbnail sketches of various compositions that he plays around with until he has a layout he is happy with. Then he moves forward with typesetting the design, making proofs to compile so he has a reference once he moves to press. “I have very strong attention to quality when printing, ensuring that the final product is printed as flawless as possible” says the printmaker. Some of Cory’s favourite printing to do is on the high-speed automatic Miehle presses; “there’s something very satisfying to me about going through the set-up and metal checklist to adjust the press to print the best quality for each and every job”.

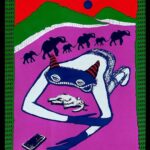

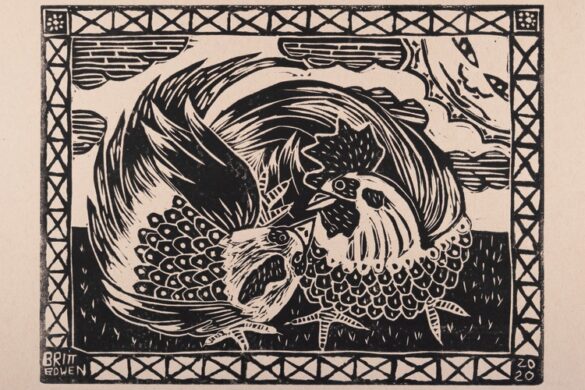

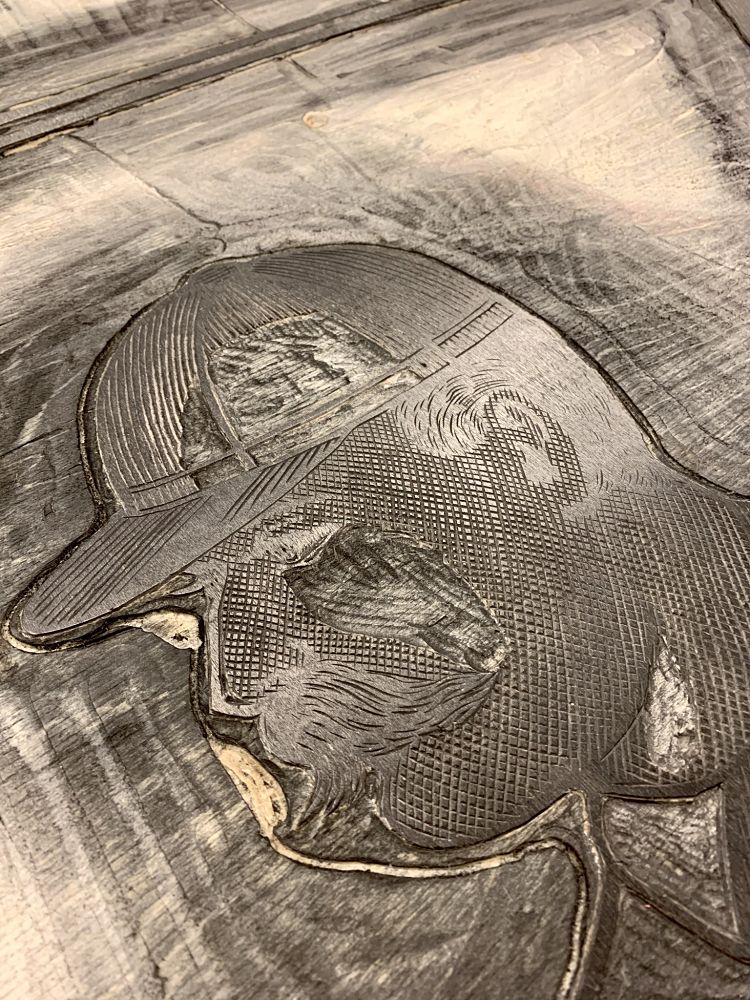

The printmaker works with a combination of wood type, metal type, and printer’s cuts for both his personal work and client custom projects. When needed, he creates digital designs and has plates made. Cory is no stranger to printing various objects for textures, such as denim, floor tiles, crumpled tape, and pennies. He states; “I like to do most of the letterpress work analogue, using tracing paper proofs to work in the physical world”. Cory has also recently begun adventuring into CNC routing for custom logos, type, and images for printing.

The printmaker works with a combination of wood type, metal type, and printer’s cuts for both his personal work and client custom projects. When needed, he creates digital designs and has plates made. Cory is no stranger to printing various objects for textures, such as denim, floor tiles, crumpled tape, and pennies. He states; “I like to do most of the letterpress work analogue, using tracing paper proofs to work in the physical world”. Cory has also recently begun adventuring into CNC routing for custom logos, type, and images for printing.

Currently, Cory is working on long-term project; a coffee table book of 60-75 of his type instruments. He has been working on the project for the past three years, creating posters of various instruments using only type and other printing blocks to create the images. Cory’s instrument prints usually start in Procreate, where he draws an instrument and all of its features using only three colours, “keeping in mind the limitations of working with the blocks that I have in my collection”. He then prints out this drawing at full scale and reversed, and uses it as a guideline for typesetting all three colours at the same time to make registration easier on the press.

Currently, Cory is working on long-term project; a coffee table book of 60-75 of his type instruments. He has been working on the project for the past three years, creating posters of various instruments using only type and other printing blocks to create the images. Cory’s instrument prints usually start in Procreate, where he draws an instrument and all of its features using only three colours, “keeping in mind the limitations of working with the blocks that I have in my collection”. He then prints out this drawing at full scale and reversed, and uses it as a guideline for typesetting all three colours at the same time to make registration easier on the press.

Cory’s pipe dream is to start a community letterpress building; “I’d like to have a place where I can work on personal work, as well as client work, but also allow others to come in and work on their own projects”. He hopes to further establish Three Cheers Press as a place offering press restoration, letterpress printing workshops, and press maintenance, led by himself and other letterpress printers and artists.

Cory’s pipe dream is to start a community letterpress building; “I’d like to have a place where I can work on personal work, as well as client work, but also allow others to come in and work on their own projects”. He hopes to further establish Three Cheers Press as a place offering press restoration, letterpress printing workshops, and press maintenance, led by himself and other letterpress printers and artists.

www.threecheerspress.com

@threecheerspress

You might like...

- KesselsKramer | Het woekert in Tolhuistuin - May 7, 2024

- Satinder Parhar | Start the Press! Artist in Residency at IKON Gallery - May 3, 2024

- Heather J. A. Thomson - May 2, 2024